In the fast-paced world of fashion, clear and precise communication is paramount. This is where the tech pack, or technical pack, steps in as an indispensable tool. Simply put, a tech pack in fashion is the comprehensive blueprint for your garment, accessory, or footwear design. It’s more than just a sketch; it’s a detailed document that designers use to communicate every aspect of their vision to manufacturers, ensuring the final product matches the initial concept. Think of it as the DNA of your fashion product, containing all the critical information needed for successful production. The quality of your tech pack directly impacts the quality of your final fashion item.

What is a Tech Pack in Fashion Design?

A tech pack, often referred to as a specification sheet or spec pack, is a collection of documents meticulously prepared by fashion designers. Its primary purpose is to articulate a design concept to a manufacturer with such clarity that they can transform it into a tangible garment. This detailed blueprint encompasses everything from precise flat sketches of the design from all angles to a comprehensive list of materials, including fabrics, trims, labels, and packaging. It also specifies exact measurements, size gradations, color palettes, and construction details.

For fashion brands engaging in outsourced garment production, a well-structured tech pack is not just beneficial—it’s often a prerequisite. Most manufacturers and factories will require a clear and comprehensive tech pack before accepting orders. This document serves as a risk mitigation tool for both parties. It precisely defines the desired specifications of the product, minimizing misunderstandings and potential errors. Ultimately, the goal of a fashion tech pack is to reduce the number of sample iterations needed and accelerate the product’s journey to market. Furthermore, the tech pack acts as a central, living document to track the entire product development lifecycle, including feedback, revisions, and any last-minute adjustments.

Why are Tech Packs Crucial in the Fashion Industry?

Tech packs are not merely good practice; they are essential for any fashion business aiming for efficiency, accuracy, and quality in their product development process. Here are key reasons why tech packs are indispensable in creating any fashion product:

Save Time and Money in Fashion Product Development

A well-crafted, easily understandable tech pack is your best defense against costly errors and delays. By providing manufacturers with a precise roadmap, you significantly increase the likelihood of receiving accurate, production-ready samples that align perfectly with your initial design vision. This reduces the need for multiple rounds of revisions, saving both valuable time and money in the long run.

Obtain Accurate Price Quotations for Fashion Manufacturing

Detailed tech packs empower manufacturers to provide more accurate price quotations. The more comprehensive your tech pack, the better a factory can assess the time, labor, and materials required to produce your garment. This transparency allows for more realistic cost estimations, preventing budget overruns and enabling informed decision-making regarding pricing and profitability.

Enhance Garment Fit Quality and Consistency

Tech packs play a vital role in achieving superior fit quality. When you receive fit samples from your manufacturer, you can use your tech pack as a benchmark. By comparing the actual measurements of the sample to the specified measurements in your tech pack’s fit sheet, you can identify discrepancies and assess whether dimensions fall within acceptable tolerances. This systematic approach allows for precise adjustments, leading to significantly improved and consistent garment fit across production runs.

Serve as a Quality Control Reference Point in Fashion Production

Throughout the sampling and production process, the tech pack serves as the definitive reference for quality control. For each sample round, you can rigorously check points of measurement, material specifications, and construction details against your tech pack. Any deviations from your outlined specifications can be clearly communicated to the manufacturer for necessary corrections, ensuring adherence to your quality standards.

Facilitate Seamless Team Collaboration in Fashion Design and Production

Beyond a static document, a tech pack can evolve into a dynamic collaborative environment. Utilizing digital tech pack platforms allows designers, product developers, buyers, and quality control teams to work together seamlessly. Real-time communication and feedback within the tech pack streamline the design and production process, fostering better products, faster turnaround times, and reduced errors.

Essential Components of a Fashion Tech Pack

The specific information included in a fashion tech pack will vary based on the complexity and type of product being developed. However, certain elements are considered standard and are crucial for most garment tech packs:

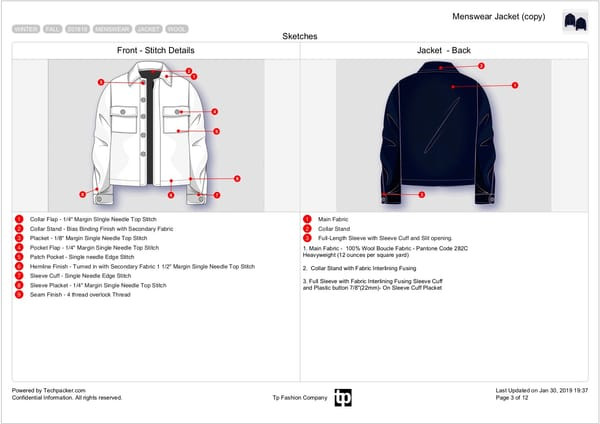

Fashion Flat Sketches: Visualizing Your Design

Technical sketches, also known as fashion flats, are black and white, technically accurate drawings of your garment. They illustrate every design detail from various perspectives—front, back, side, and even interior views. These sketches are essential for helping manufacturers and pattern makers visualize the design and create initial samples that closely resemble your intended look. Typically created using software like Adobe Illustrator, these sketches prioritize clarity and precision over artistic rendering.

Ensuring you have complete and detailed garment or accessory sketches before initiating your tech pack is paramount. Here are key tips for creating professional flat sketches for your fashion tech packs:

Include Multiple Views for Clarity:

Presenting various viewpoints, such as side views, internal label placements, and intricate details, significantly enhances a manufacturer’s understanding of the garment’s construction. Supplement these sketches with written notes detailing any aspects of the garment that aren’t immediately apparent in the visuals. This often includes diagrams with labeled arrows indicating specific features like collars, plackets, cuffs, fastenings, bar tacks, and artwork placement.

Maximize Detail and Precision:

Strive for thoroughness and meticulous attention to detail in your sketches. Omitting elements or being vague will only complicate the communication of your design to the factory. Every seam, dart, stitch type, and button placement should be accurately represented. In technical sketches, solid lines generally denote seam lines, while dashed lines typically indicate stitching. Ensure that every detail referenced in your tech pack is visually represented in your sketches.

Maintain Simplicity and Focus on Technical Accuracy:

While detail is crucial, avoid overcomplicating your sketches with unnecessary artistic elements. Steer clear of shading, color, or overly stylized representations. Opt for clean, black and white sketches to ensure your design is communicated clearly and technically. The focus should be on conveying construction and technical specifications, not artistic impression.

Bill of Materials (BOM): Listing Essential Components

The Bill of Materials (BOM) is a comprehensive inventory of all raw materials required to produce a single unit of your garment and prepare it for shipping. For any fashion business producing physical products, sourcing materials is a fundamental step in the production process. The quality and type of materials you select profoundly impact the final product.

A standard BOM table typically includes main fabric, lining or secondary fabrics, thread types, trims (zippers, buttons, etc.), closures (snaps, hooks), labels (care, brand, size), and packaging materials.

In the fashion industry, technical designers and product developers usually collaborate to create the BOM. These professionals work closely, often exchanging feedback with factories to refine the tech pack. Technical designers often base the BOM on CAD (Computer-Aided Design) drawings, ensuring accuracy and integration with the design specifications.

A well-defined BOM table offers several key advantages:

- Accurate Costing and Pricing: It is essential for determining the precise cost of garment production, which directly informs pricing strategies and profitability calculations.

- Component Completeness: It acts as a checklist for manufacturers, ensuring no necessary components are overlooked during production.

- Manufacturing Standardization and Quality Control: It standardizes the manufacturing process, guaranteeing consistency and quality across different production batches.

Garment Measurement Specs: Ensuring Precise Fit

Once the style, sketches, and materials are defined in your tech pack, the next critical step is to include detailed measurements. The Measurement Specification Sheet, often called a spec sheet or garment spec sheet, provides an exhaustive breakdown of measurements for various components of the garment.

While general measurement terms like body length, chest, waist, hips, armhole, shoulder drop, and neck opening are commonly used in almost every measurement sheet, the complexity of the garment dictates the number of measurement points required. For more intricate designs, additional measurements such as collar length/width, cuff length/width, and pocket dimensions become necessary.

The garment measurement sheet is arguably one of the most vital documents in the entire clothing production process. Errors in the spec sheet can lead to significant time and financial losses for designers, resulting in garments that do not fit as intended.

Measurement spec sheets can be developed based on standard industry sizing charts or tailored to custom body measurements, depending on the target market and brand specifications.

Garment Cost Sheet: Calculating Production Expenses

A garment cost sheet is specifically designed to calculate the complete cost of producing a single garment. A typical cost sheet encompasses material costs, labor expenses, and processing costs.

Each fashion product, due to its unique specifications, requires a distinct costing table. However, all garment cost sheets share essential elements that must be included. The level of detail in a cost sheet is directly related to the garment’s complexity.

To accurately calculate the final cost, every component involved in manufacturing must be clearly itemized. This includes main fabric, lining, interfacing, trims, buttons, zippers, embellishments, appliques, and more. The costing table should list all these details, preferably with quantities for each item in a separate column to facilitate clear visualization and calculation.

Certain items are universally applicable across garment types, such as tags, labels, sewing thread, and packaging materials. These should always be included in any costing table, regardless of the specific product being created.

How to Create a Tech Pack for Fashion

Traditionally, Microsoft Excel has been the go-to tool for creating tech packs in the fashion industry. Its versatility, extensive features, and familiar spreadsheet format made it a seemingly logical choice. However, this reliance on spreadsheets presents several significant challenges.

The primary drawbacks of using spreadsheets for fashion tech packs include:

- Lack of Real-time Team Communication: Tech packs are inherently collaborative documents, typically involving design teams, product developers, and manufacturers. Spreadsheets hinder real-time collaboration. Tech pack versions are often exchanged via email, leading to communication silos and delays in product development cycles.

- Static and Disjointed Information: Spreadsheets are static by nature. Product information is often segmented into multiple tabs and files, making the tech pack fragmented and difficult to visualize holistically. This disjointed approach increases the likelihood of errors and inconsistencies.

- Inefficient for Seasonal Collections: Creating tech packs season after season in Excel is slow and inefficient. Product information is not easily reusable, requiring significant manual data entry for each new collection. Repurposing design details involves cumbersome copying and pasting, increasing the risk of errors and inconsistencies in measurements and formulas.

Fortunately, modern, cloud-based software solutions like Techpacker are transforming the tech pack creation process, streamlining product development and mitigating production delays.

Unlike Excel, Techpacker’s visual approach offers a comprehensive overview of your entire product development process at a glance. You don’t need to navigate between multiple tabs to review or edit different sections of your tech pack.

Sketches, Bill of Materials, Point of Measurements, Costing Tables—everything is visually accessible on a single, unified page. And with a single click, this visual board can be instantly converted into a production-ready PDF tech pack, ready to be shared directly with your manufacturer.

Furthermore, Techpacker facilitates design specification reuse across collections through its card libraries. Each card securely stores design information such as sketches, measurements, or materials, allowing for efficient repurposing in future tech packs.

Direct team collaboration is also enhanced through card-based comments and tagging features. Real-time communication directly within the tech pack environment significantly accelerates the product development process, reduces miscommunication, and fosters a more efficient workflow.

Tech Pack Fashion Examples and Templates

To further illustrate the practical application of tech packs in fashion, here are several examples of detailed tech packs created using Techpacker:

Wrap Dress Tech Pack Example

View Now Copy Template

Menswear Jacket Tech Pack Example

View Now Copy Template

Women’s Shoulder Bag Tech Pack Example

View Now Copy Template

Bed Linens Tech Pack Example

View Now Copy Template

Fitted Denim Jeans Tech Pack Example

View Now Copy Template

Lingerie Bodysuit Tech Pack Example

View Now Copy Template

Dining Chair Tech Pack Example (Illustrating Tech Packs Beyond Apparel)

View Now Copy Template

Video: The 5-Minute Tech Pack Challenge

Witness the speed and efficiency of modern tech pack creation! This video demonstrates how a factory-ready tech pack can be generated in just 5 minutes, highlighting the power of streamlined digital tools.

Bonus Resource: Download Our Free “Ultimate Guide to Tech Pack in Fashion” Ebook!

Sign up below to download this comprehensive ebook and deepen your understanding of tech packs in fashion.