Creating a product in the fashion industry is a detailed, step-by-step journey. It begins with initial design concepts and fashion flat sketches, and culminates in a finished garment ready for consumers. A crucial phase in this process is developing clear and precise Fashion Specs, and a key document within these specs is the garment spec sheet, also known as a measurement table.

A garment spec sheet is an essential part of a tech pack. It acts as a detailed communication tool where designers provide manufacturers with all the technical instructions and criteria needed to accurately produce a garment. But what exactly is a garment spec sheet, and how do you create one effectively as part of your fashion specs package? Let’s delve into the specifics.

What is a Garment Spec Sheet in Fashion Specs?

A garment specification (spec) sheet, or measurement table, is a technical document that forms a core component of fashion specs. It meticulously outlines all the construction details for a garment. Imagine it as a technical blueprint or diagram of your design, complete with all necessary measurements. Designers use spec sheets to effectively communicate their design vision and technical requirements to manufacturing teams, ensuring accurate production.

Key Components of a Garment Specification Sheet in Fashion Specs:

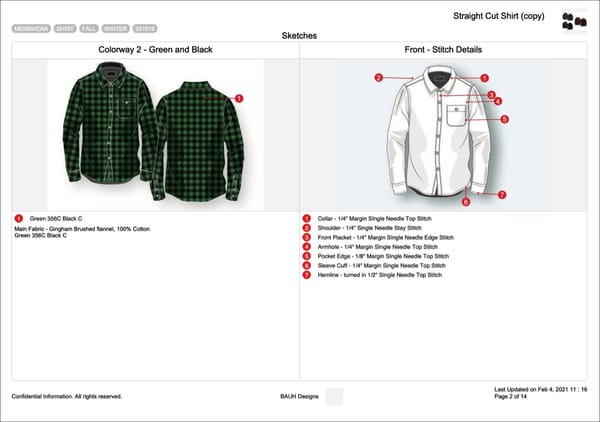

- Garment Sketches: Typically includes front and back views. For complex designs, additional detailed views might be necessary to clarify specific features.

- Measurement Sheet for All Sizes: A comprehensive table detailing measurements for each size variant of the garment.

- Construction Guidelines: Instructions on how the garment should be constructed, including specific assembly steps.

- Stitching Details and Seam Types: Specifications for the types of stitches and seams to be used in different parts of the garment, impacting both aesthetics and durability.

- Additional Comments: Any extra notes or special instructions that are crucial for the manufacturer to understand and execute the design accurately.

Let’s examine an example of a garment spec sheet to better understand its elements within fashion specs.

This spec sheet is then used by the manufacturer as a blueprint to create the garment pattern, grade it for different sizes based on the provided fashion specs, and finally, construct a sample garment for review.

The initial specification sheet is not always final. Often, after the first sample is produced, adjustments are needed. Any necessary changes are recorded and incorporated back into the original spec sheet. The example spec sheet is updated to reflect these adjustments and comments. Once a final sample is approved, it signifies that the fashion specs are finalized, and bulk production can commence.

How to Determine Points of Measurement (POM) and Specs in Fashion Specs

Once the design is finalized and initial body measurements are available, the next step in defining fashion specs is to determine the garment measurements, or specs. Some measurements are derived directly from body measurement data, while others are adjusted to incorporate ease, which is the amount of extra fabric added for comfort and movement.

To illustrate how garment measurements are determined within fashion specs, let’s consider the example of a Bell Sleeve Top.

As indicated in the sketch, this is a looser-fitting garment, meaning it will require a significant amount of ease, particularly around the sleeve openings to achieve the bell shape. When developing a spec sheet for a top within your fashion specs, it’s essential to include key measurements such as chest, waist, hem, shoulder width, and armhole circumference to ensure the desired fit.

For this example, we’ll assume the garment is made from woven fabric. Woven fabrics, lacking stretch, generally require more ease compared to knit fabrics. For a loose-fitting woven garment, a common guideline is to add 6-8 inches of ease at the bust. If our base size body has a chest measurement of 34 inches, we might aim for a 40-inch full chest width for the garment, or 20 inches for the half chest measurement, as part of our fashion specs.

This process is then repeated for all necessary Points of Measure (POM) to create a complete set of garment specs. Each measurement point contributes to the overall fit and design intent defined within the fashion specs.

An important factor to consider when creating your fashion specs is tolerance in production. Tolerance refers to the acceptable range of variation (often expressed as +/-) above or below the specified measurement that a garment can have and still pass quality control.

Several factors in the sewing and construction process can lead to slight variations in final garment measurements. These potential variances must be accounted for in the fashion specs. Typically, larger body measurements like chest or hip areas have a tolerance of +/- ½ inch, while smaller areas like sleeve width or neck drop will have tighter tolerance amounts.

When setting tolerance levels in your fashion specs, it’s crucial to strike a balance. Tolerances should be large enough to accommodate necessary variations in production but small enough to prevent size overlap. For instance, if size S has an 18-inch half chest and size M has a 19.5-inch half chest, a 1-inch tolerance would be problematic. It could lead to size S garments measuring up to 19 inches and size M garments measuring down to 18.5 inches, causing confusion and inconsistency for customers. By limiting the tolerance to +/- ½ inch, you ensure that the largest possible size S is 18.5 inches, and the smallest possible size M is 19 inches, thus avoiding size crossover and maintaining consistent sizing within your fashion specs.

How to Create a Measurements Table for Fashion Specs

Garment spec sheets, or measurement tables, which are integral to fashion specs, are typically developed using templates in spreadsheet programs like Excel or specialized tech pack software. Once completed, the file is usually formatted as a PDF and sent to the manufacturer along with the complete factory-ready tech pack, ensuring all fashion specs are clearly communicated.

To create a measurement table, you will need to measure your sample garment accurately. To understand measurement techniques and ensure accuracy, you can consult guides on apparel sizing and measuring.

For a men’s jacket, for example, the measurements that are typically included in the measurement table within fashion specs are:

- Total garment length

- Hip, waist, and chest circumference

- Shoulder width

- Sleeve length, cuff width, and armhole circumference

- Pocket width and length

Let’s look at an example of a measurement table for a men’s jacket, demonstrating how fashion specs are documented.

After inputting the measurements for the sample size (in this example, size M), a tolerance range is provided. This tolerance range is specified for each Point of Measurement to assess each sample size against the defined fashion specs. This allows for requesting adjustments if samples fall outside the acceptable tolerance.

Next, the garment is graded for different sizes. Specialized software designed for tech pack creation, such as Techpacker, offers auto-grading functionality based on pre-defined grading rules. This significantly accelerates the grading process and minimizes errors, ensuring consistency across all sizes within your fashion specs.

Point of measurement diagrams provide a visual representation of your measurements. Using sketch diagrams with labeled arrows clearly indicates where each measurement point is located on the garment. These diagrams are typically created in software like Adobe Illustrator alongside the technical sketch of the garment. Techpacker simplifies this process by allowing users to add callout annotations directly within the platform, streamlining the creation of fashion specs.

Here is an example of a point of measurement diagram for a pocket, illustrating how detailed fashion specs are visually communicated. It includes points of measurement such as pocket width, length, and flap length.

As illustrated, callout annotations are invaluable for clarifying how measurements should be taken by the manufacturer, minimizing errors and ensuring accurate interpretation of fashion specs.

For a comprehensive view of the complete spec sheet for the men’s Shirt, you can refer to this link.

How to Reuse Measurement Tables as Templates in Fashion Specs

Creating detailed measurement tables as part of your fashion specs might initially seem like a significant undertaking. However, many points of measurement are often reusable across multiple tech packs. There’s no need to recreate them from scratch for every new design.

Measurements such as collar width, neck drop, sleeve length, cuff width, and pocket measurements are frequently consistent and can be easily reused in seasonal collections and new projects. Having these pre-defined and readily available can save considerable time when building new tech packs and ensure consistency across your fashion specs library.

Techpacker offers the capability to create templates for future reuse within your measurement tables. You and your team can easily access and apply these saved templates to any tech pack with just a few clicks. This feature not only saves time but also maintains measurement consistency across numerous tech packs, contributing to streamlined and efficient fashion specs management.

Save selected measurements as cards for future reuse | Ready to create your own spec sheet? GET A FREE TECHPACKER TRIAL OR Request a demoManage your product development to production workflow with factories hassle-free. Try Techpacker. |

|—|